Which Way Is To Loosen A Screw: Complete Guide & Key Details

Hey there, fellow humans! Ever found yourself staring at a screw, a tiny metal enigma, and wondered, "Which way does this thing actually go?" You're not alone. We've all been there, fumbling with a screwdriver, hoping for the best, and sometimes, well, not getting it. It's like trying to unlock a secret door, and you've got the wrong key in your hand.

But fear not! This isn't rocket science, though sometimes it feels like it when you're trying to assemble that IKEA furniture or fix a wobbly chair. Understanding the simple magic of screw direction can save you a whole lot of frustration and maybe even prevent a minor household disaster. Think of it as unlocking a superpower, a tiny, yet incredibly useful, superpower for your everyday life.

The Big Secret: Righty Tighty, Lefty Loosey!

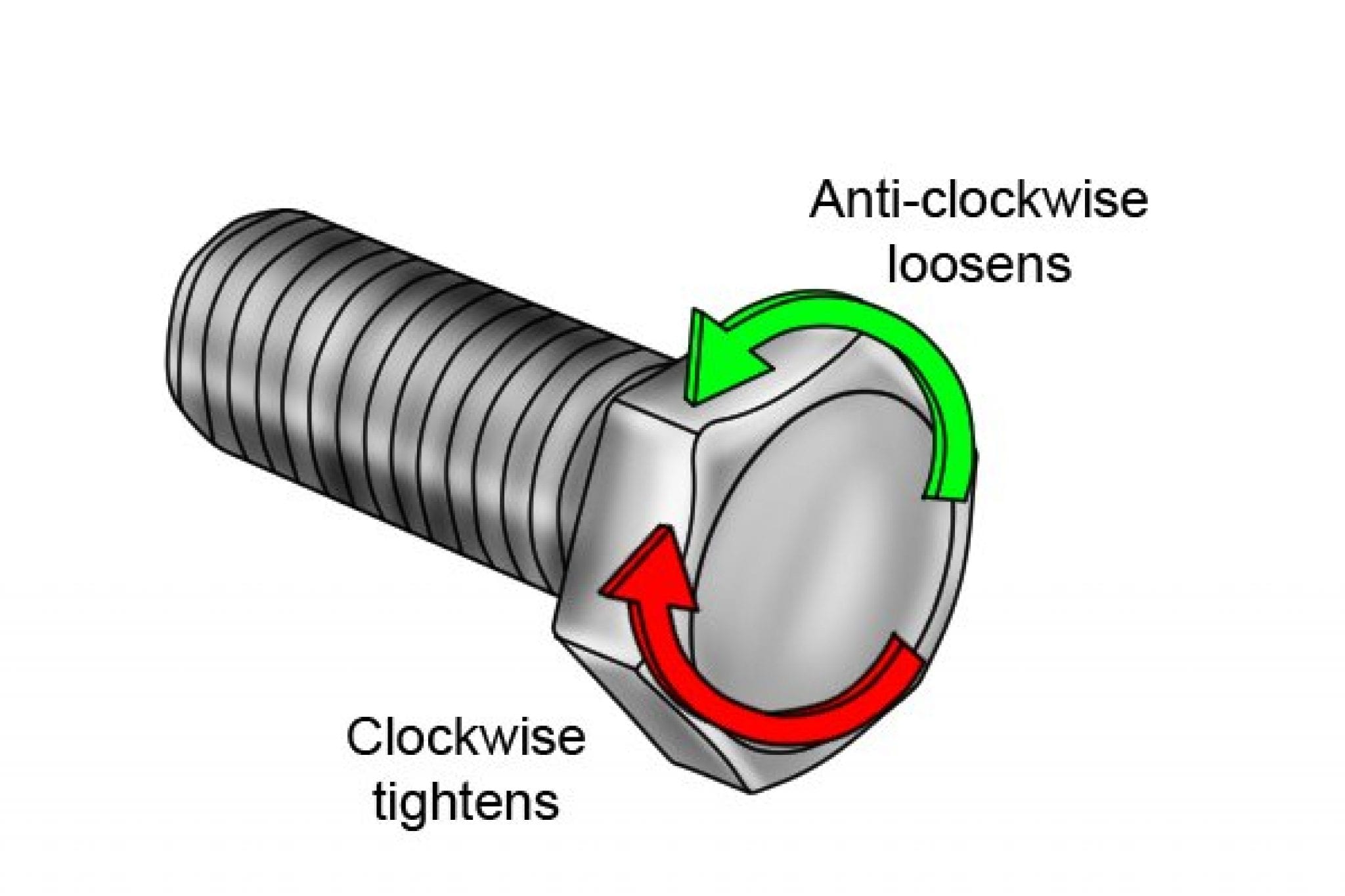

Okay, drumroll please... the fundamental rule, the golden commandment of screw turning, is this: Righty tighty, lefty loosey. Got it? Say it with me: Righty tighty, lefty loosey. It’s basically a catchy little rhyme that’s going to be your new best friend when you encounter a screw.

Imagine you're giving a friendly pat on the back to a screw to make it go in. That's turning it to the right, and it's going to get tight. Simple, right? Now, imagine you're trying to gently coax that screw out. You're turning it to the left, and it's going to become loose. It’s like unwinding a spool of thread – you go left to unravel.

This rule applies to the vast majority of screws you'll encounter. From the tiny ones holding your glasses together to the beefy ones keeping your bookshelf from doing a dramatic floor performance, they all generally follow this clockwise-to-tighten, counter-clockwise-to-loosen dance. It’s the universal language of fasteners.

Why Should You Even Care About Screw Direction?

You might be thinking, "Big deal. I'll just try both ways and see what happens." And sure, for a loose shelf or a wonky picture frame, that might work. But let's think about the bigger picture, or rather, the smaller, more important picture of your belongings.

First off, efficiency! Knowing the right way saves you precious time. Instead of a ten-minute wrestling match with a screw, it becomes a quick, satisfying twist. Think of all the other amazing things you could be doing with that saved time – perfecting your sourdough starter, binge-watching that new series, or maybe even learning a new language. The possibilities are endless!

Secondly, damage prevention. Trying to force a screw in the wrong direction is like trying to push a square peg into a round hole. It doesn't fit, and you're going to end up damaging the screw, the material it's going into (your precious furniture, your car door, etc.), or both. We’ve all seen those stripped screw heads that look like they've been through a tiny, aggressive wrestling match. It’s not a good look, and it makes future removal a nightmare.

And let's not forget the satisfaction. There's a quiet joy in successfully completing a task, especially a seemingly simple one. That satisfying click or smooth turn when you get it right? Pure, unadulterated accomplishment. It’s the little victories that make life sweeter, and mastering screw direction is one of them!

Different Types of Screws, Same Basic Rule (Mostly!)

Now, while "righty tighty, lefty loosey" is your guiding star, the world of screws isn't entirely uniform. There are a few interesting exceptions and variations to be aware of, but they're less common and usually in specific applications.

The Standard Screw: Your Everyday Hero

These are the ones you'll see everywhere. Think of the screws holding your electrical outlet cover, the ones in your computer's casing, or the ones that keep your cabinet doors attached. They are almost always designed to be tightened by turning to the right (clockwise) and loosened by turning to the left (counter-clockwise).

Imagine you're tightening a bolt on your bicycle to keep the wheel secure. You’re turning it clockwise. If you ever need to remove that wheel, you’ll be turning it counter-clockwise. It’s all about making things secure, and then making them come apart when you need them to.

The Rare Exception: The "Left-Hand Thread" Screw

This is where things get a tiny bit tricky, but don't let it scare you! These are called left-hand thread screws. And yes, you guessed it – they work the opposite way. You tighten them by turning to the left and loosen them by turning to the right. Shocking, I know!

Why do these exist? Usually, they're used in situations where the rotation of the object might naturally try to loosen a standard screw. For example, on some bicycle pedals, the left pedal might have a left-hand thread. This is because as you pedal, the motion can create a force that would loosen a regular screw. By using a left-hand thread, the pedaling motion actually helps to tighten it!

Another place you might find them is on the spindle of some very old or specialized machinery. If you ever encounter a screw that really doesn't want to go in when you're turning it right, and it feels strangely loose when you turn it right, there's a slight chance you've found a rare lefty. Give the other way a gentle try, but always be cautious not to force anything.

How to Identify Which Way to Turn

So, how do you know if you're dealing with a standard screw or one of those quirky lefties? Here's your handy-dandy guide:

1. The Visual Clue: The Threads

Look closely at the screw threads. If they angle upwards from left to right as they go into the screw head, it's a standard right-hand thread. If they angle downwards from left to right, it's a left-hand thread. It's a subtle difference, and sometimes hard to see in low light or with tiny screws. So, don't rely solely on this unless you have a magnifying glass and impeccable eyesight!

2. The "Test Turn" (Gentle Edition!)

This is your most reliable method. Start with the most common rule: try turning it to the right. If it starts to go in (tighten) or comes out (loosen) with a smooth, steady motion, you've likely got a standard screw. If it feels like it's just grinding or jamming, or you’re meeting significant resistance in the direction you’d expect it to tighten, then you might consider trying the other direction.

Crucially, do this gently! Don't go full Hulk on it. A little resistance is one thing, but forcing it is what leads to stripped heads and broken parts. If you apply a little pressure in one direction and it doesn't budge, and then a little pressure in the opposite direction makes it move, bingo! You've found your answer.

3. When In Doubt, Look for Context

Sometimes, the context of where the screw is located can give you a hint. Is it part of a mechanism that rotates? If so, think about how that rotation might affect a standard screw. For instance, if a part is constantly spinning in a certain direction, the engineers might have deliberately used a left-hand thread to prevent it from loosening over time. Think of a car's wheels – they spin forward, so the lug nuts need to tighten as they spin forward.

Common Mistakes and How to Avoid Them

We've all made them, so let's laugh about them and learn!

The "Too Much Torque" Tango

This is the classic mistake. You're trying to tighten a screw, and you just keep going. You want it super secure. Suddenly, you hear a dreadful crunch, or the screw head feels… wiggly. You've gone too far and stripped the screw head or damaged the threads in the material. Lesson: Stop when it feels snug and secure, not like you're trying to win a power-lifting competition.

The "Wrong Tool" Fiasco

Trying to use a butter knife as a screwdriver is a recipe for disaster. You'll likely damage both the "screwdriver" and the screw head. Make sure you're using the correct type and size of screwdriver for the screw head (Phillips, flathead, Torx, etc.). It’s like using a proper kitchen knife for chopping vegetables – it just works better and safer.

The "Blind Guess" Blunder

Flipping a coin to decide which way to turn is rarely the best strategy. Take a second, remember "righty tighty, lefty loosey," and try to apply it. If you're unsure, a gentle test turn is far better than a forceful, incorrect turn.

Conclusion: You've Got This!

So there you have it! The seemingly simple act of turning a screw is actually governed by a pretty straightforward rule. Mastering "righty tighty, lefty loosey" will make your DIY adventures smoother, your repairs quicker, and your frustration levels significantly lower. It’s a little piece of knowledge that pays off big time in everyday life.

Next time you face a screw, don't sweat it. Just take a breath, remember the rhyme, and give it a gentle turn. You’ll be a screw-turning samurai in no time. Happy fixing, building, and unbuilding!