What Size Drill Bit To Tap M6: Complete Guide & Key Details

You know, I remember the first time I tried to tap an M6 thread. I was so excited. I’d just bought this fancy piece of hardware, a little brass hinge for a birdhouse I was building. It was beautiful. And, of course, it had these tiny little holes that needed threads so I could screw it on. Easy peasy, right? I grabbed what I thought was the right drill bit, a bit of metal that looked about the right size. I’d seen people do it on YouTube, looked pretty straightforward. A few turns, and voilà, a perfect thread!

Well, let me tell you, my birdhouse ended up looking less like a charming woodland abode and more like it had a very intimate encounter with a very angry badger. The thread was… well, let's just say it was enthusiastic but definitely not accurate. The screw wouldn't go in, or if it did, it felt like it was fighting its way through a cheese grater. Disaster!

It turns out, picking the exact right drill bit is kind of a big deal. Like, a really, really big deal. It’s not just about getting a hole; it’s about getting a hole of a specific size to create a thread that will actually work. And for M6 threads, there’s a magic number. Today, we’re going to dive into the nitty-gritty of what size drill bit you need to tap an M6 thread, and why it matters so much.

The M6 Mystery: What's the Magic Number?

So, what’s the deal with M6? In the world of threading, "M" stands for metric, and "6" refers to the nominal diameter of the screw, which is 6 millimeters. Simple enough, right? But here’s where it gets a tiny bit less obvious. You don’t just drill a 6mm hole to tap an M6 thread. Why? Because you need enough material left over for the tap to actually cut those nice, clean threads. If the hole is too big, there's nothing for the tap to bite into.

The standard pitch for an M6 thread is 1 millimeter (this is called a coarse thread). This means the distance from the crest of one thread to the crest of the next is 1mm. When you're tapping, the tap effectively shaves away metal to create these grooves. You need a hole that’s slightly smaller than the full 6mm diameter to allow for this cutting action.

So, the drill bit size you’re looking for to tap a standard M6 thread is 5 millimeters. Yep, just 5mm. It seems counterintuitive, I know! But trust me, this is the number you want etched into your brain, tattooed on your knuckles, or at least written down somewhere you won't lose it. (Maybe not the knuckle tattoo, unless you're really committed to your craft).

Why 5mm? Let's Get Technical (But Not Too Technical)

Alright, let’s break down the geometry without getting a headache. A screw thread has an major diameter (the widest part of the screw, which is our 6mm for M6) and a minor diameter (the narrowest part, at the root of the threads). When you drill a hole for tapping, you’re essentially creating the space that will become the internal major diameter of your tapped hole. The tap then cuts the internal minor diameter.

The ideal drill size is determined by the thread's pitch and the desired thread height. For a standard M6 coarse thread (1mm pitch), a 5mm drill bit leaves just the right amount of material for the tap to create a thread that's about 75% to 80% of its full height. This is generally considered the sweet spot for strength and ease of tapping. If you drill too small, the tap might break or you’ll have a really tight thread that’s hard to screw into. Too big, and you won’t have enough thread engagement.

Think of it like this: imagine you’re trying to carve a groove into a piece of wood. If the wood is too thin, you can’t make a deep groove. If it’s too thick, you might not be able to make a groove at all. You need that perfect thickness of material for the cutting tool to do its job effectively.

When the Standard Isn't Standard: Fine Threads and Other Shenanigans

Now, before you go running off and drilling 5mm holes for every M6 situation, there’s a small asterisk to this rule. Most of the time, when people talk about M6, they mean the standard coarse thread. But, like a plot twist in a thriller, there are also fine-pitch M6 threads. These are less common for general DIY stuff, but you might encounter them in machinery or specialized applications.

A fine-pitch M6 thread typically has a pitch of 0.75mm or 0.5mm. Because the threads are closer together, you need a slightly larger drill bit to accommodate them. For an M6 x 0.75mm thread, you’d typically use a 5.25mm drill bit. And for an M6 x 0.5mm thread, you'd step up again to a 5.5mm drill bit. See? It’s a whole world of precision!

How do you know if you have a fine-pitch thread? The easiest way is to look at the packaging or any markings on the screw or bolt. It will usually specify the pitch, like “M6 x 0.75”. If it just says “M6,” it’s almost certainly the standard coarse thread.

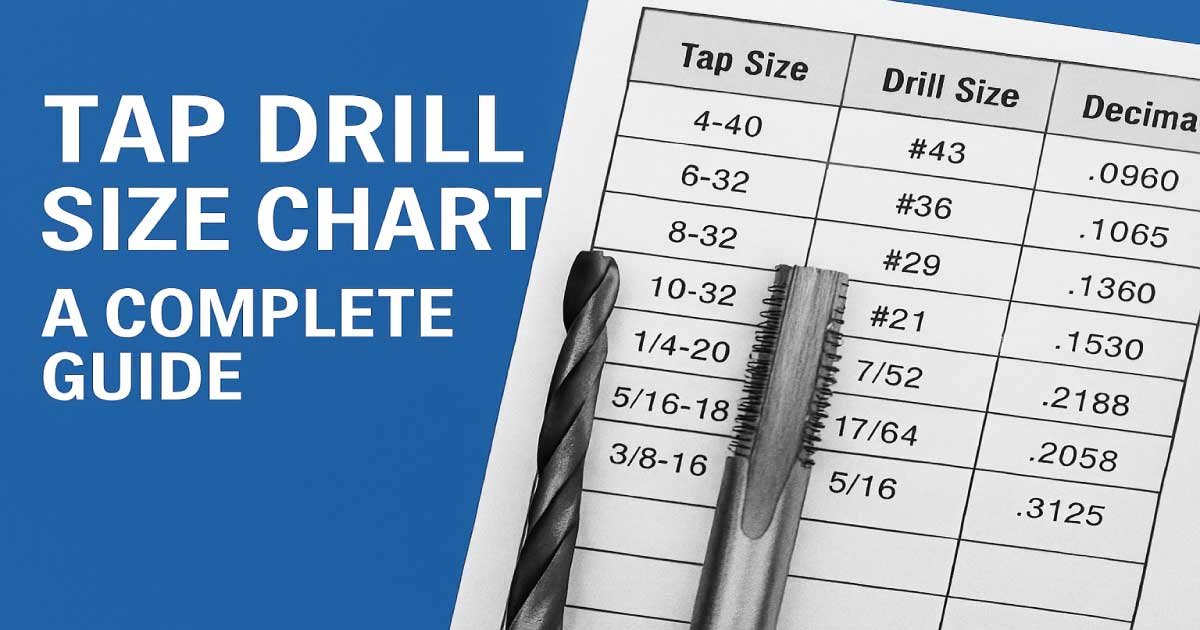

What About That Other Tool? The Tap Drill Chart

If you’re a visual learner, or if you just like having handy references, a tap drill chart is your best friend. These handy charts list all the common tap sizes (like M6) and the corresponding drill bit sizes you should use for both coarse and fine threads. You can find them online, in hardware stores, or even printed in the back of some tool catalogs.

Seriously, get one. Keep it in your toolbox. It’s the ultimate cheat sheet. It’s like having a wise old mentor whispering the correct answer in your ear just when you need it. Plus, it saves you from that sinking feeling of realizing you’ve just drilled the wrong size hole again.

The Tapping Process: Beyond Just the Drill Bit

Okay, so you’ve got the right drill bit (5mm for standard M6). Hooray! But drilling is only half the battle, right? The actual tapping is where the magic (or mayhem) happens. Let me give you a few pointers to make sure your threading journey is more smooth sailing and less badger attack.

Preparation is Key, My Friend

First things first: center punch your starting point. This is crucial! It prevents your drill bit from wandering and ensures you drill your hole precisely where you intend it to be. A little dimple is all you need.

Then, when you drill, go straight. As straight as possible. An angled hole will result in a crooked thread, which is less than ideal. If you’re drilling into a thin piece of material, consider using a drill press for maximum accuracy. If you’re doing it freehand, take your time and keep your drill perpendicular to the surface.

Lubrication: The Secret Sauce

This is a big one, people! Lubrication is your best friend when tapping. Use a cutting fluid, tapping fluid, or even a bit of motor oil. Why? It helps reduce friction, keeps the tap cool (which prevents it from getting gunked up and breaking), and makes it easier for the tap to cut the metal smoothly. It’s like oiling squeaky hinges – things just work better when they’re well-lubricated!

The Art of the Tap: A Gentle Touch

When you start tapping, use a tap wrench or a suitable handle. Insert the tap into the hole, making sure it’s perfectly square. Now, here’s the technique: turn the tap about one full turn to the right (to cut) and then about a half turn back to the left (to break the chip). Repeat this process.

This back-and-forth motion is essential. It breaks off the small pieces of metal (chips) that the tap cuts, preventing them from clogging the tap flutes and causing it to bind or break. If you feel a lot of resistance, don't force it. Back it off, clear the chips, apply more lubricant, and try again. Patience is a virtue, especially when dealing with sharp metal.

The Bottom Line: Don't Rush!

Honestly, the biggest mistake people make is rushing the process. They want to get it done quickly, and that’s when things go wrong. Take your time, be methodical, and enjoy the process of creating something with your own hands. There’s a real satisfaction in a perfectly tapped thread.

So, To Recap: The Golden Rule for M6

Let’s bring it all home. For a standard M6 coarse thread (the most common one), the drill bit size you need is 5 millimeters. If you’re dealing with an M6 fine thread, check the specifications, but generally, you’ll be looking at 5.25mm or 5.5mm. Always refer to a tap drill chart if you’re unsure.

Remember the lubrication, the back-and-forth turning, and the general principle of not forcing anything. With the right drill bit and a bit of patience, you’ll be tapping M6 threads like a pro in no time. And who knows, maybe your next birdhouse will be so charming, the birds will start charging you rent!

Happy tapping, everyone!