How To Weld With A Tig Welder (step-by-step Guide)

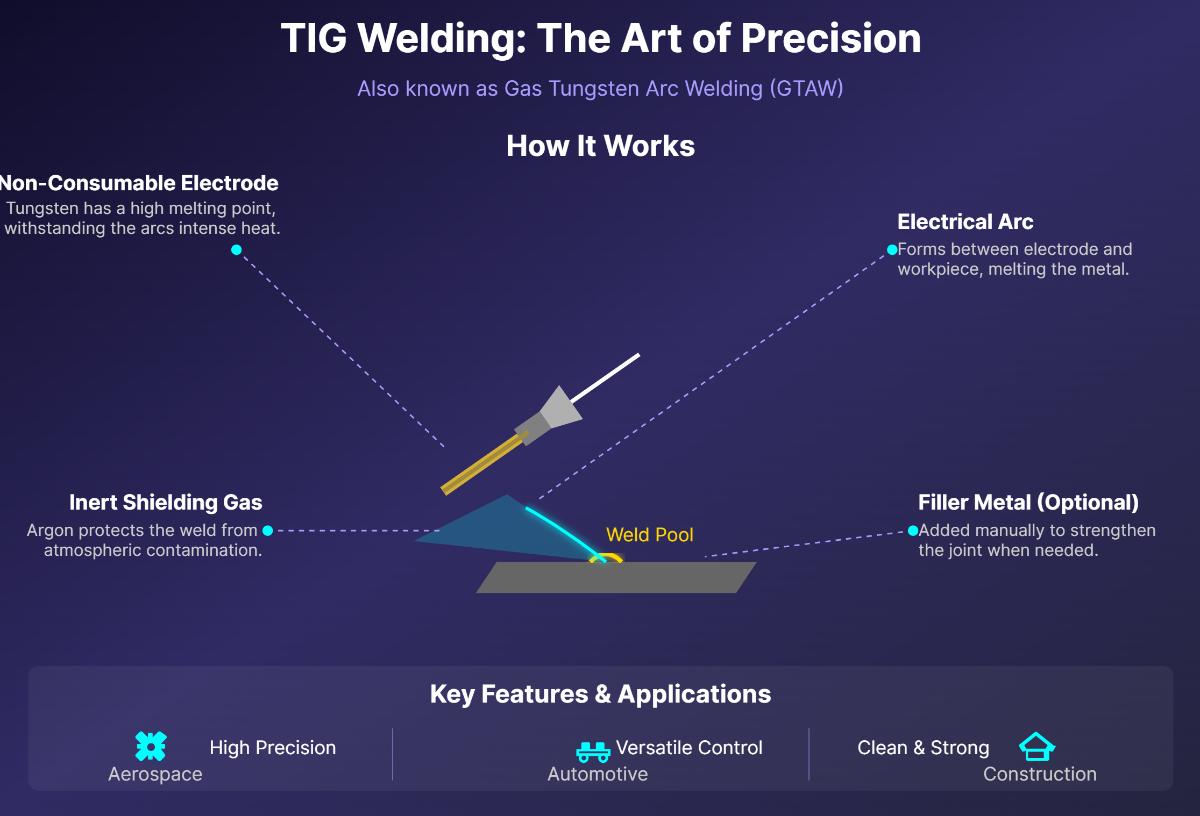

So, you’ve stumbled upon the mystical world of TIG welding. Maybe you’re eyeing up that shiny new welder in the garage, or perhaps a buddy’s been bragging about his fancy argon tank, making you feel a bit like you’re missing out on the secret handshake of metal manipulation. Fear not, aspiring metal maestro! TIG welding, or Gas Tungsten Arc Welding if you want to sound fancy at a party (though honestly, who does that?), is less about rocket science and more about a dance between you, your machine, and a very hot, very precise little spark. Think of it like trying to delicately paint a masterpiece with a tiny, super-powered paintbrush that also happens to melt metal.

Forget those clunky, angry sparks you might associate with some other welding methods. TIG is the sophisticated cousin of welding. It’s the one that sips tea while the others are chugging energy drinks. It’s all about control, precision, and making those metal joints look so clean you could practically frame them. And yes, it can be a bit intimidating at first. It’s like learning to juggle flaming torches while blindfolded – but with practice, it becomes surprisingly… well, not easy, but definitely doable and even kinda zen.

We’re going to break this down, step-by-step, with zero jargon overload. Imagine we’re just hanging out, maybe over a couple of cold ones, and I’m showing you how to make some metal do your bidding. No need to don a full hazmat suit and a degree in metallurgy just yet. We’re aiming for smiles, nods of recognition, and maybe a triumphant “Hey, I can actually do this!”

Gearing Up: The Essential Tools of the Trade (No, Not a Cape)

Before we get our hands dirty (or rather, our gloves dusty with fine metal particles), we need to make sure we’ve got the right gear. This isn't like heading out for a picnic where you just need a blanket and some cheese. Welding is a bit more involved, but not so much that you’ll need to sell a kidney. Let’s talk about the essentials.

The TIG Welder Itself: Your New Best Friend (Probably)

This is the heart of the operation. You’ll have a power source, which is basically the brain. It’s what generates that magical electricity. Most modern TIG welders are pretty user-friendly. You’ll see knobs and buttons that look a bit like a spaceship control panel, but don't let that scare you. We’re mostly concerned with a few key settings initially. Think of it like learning to drive a car – you don’t need to know how the engine works to get from A to B, just how to steer and press the pedals.

You’ll probably see terms like AC and DC. For most beginners tackling common metals like steel or stainless steel, DC is your jam. AC is usually for aluminum, which is a whole other level of fancy TIGing. So, for now, let’s focus on DC. You’ll also have amperage control. This is like the volume knob for your welding power. Too low, and you’re just kinda tickling the metal. Too high, and you’re going to make a hole bigger than your ambition.

The TIG Torch: Your Wand of Power

This is the pointy bit you’ll be holding. It’s where the magic happens. It houses the tungsten electrode, which is a special rod that doesn’t melt (unlike the metal you’re trying to join – confusing, right?). You’ll have a trigger on it to start and stop the welding arc. Some have foot pedals, which is like having cruise control for your amperage – very handy for finer control, but let's keep it simple for now with a trigger start.

Inside the torch, there’s also a gas nozzle. This is where the magic gas, argon, comes out to create a protective shield around your molten puddle. Think of it as a tiny, invisible force field keeping the oxygen dragons away from your precious metal.

Shielding Gas: The Invisible Bodyguard (Argon, Usually)

This is your argon. Pure argon is the standard for most TIG welding. It's an inert gas, meaning it doesn't react with anything. Its job is crucial: it blows away all the nasty atmospheric contaminants (like oxygen and nitrogen, the metal’s sworn enemies) from the weld zone. Without it, your welds would look like a rusty, bubbly mess. It’s like trying to bake a cake with the oven door wide open and a fan blowing – not going to end well. The gas comes from a big cylinder, and you’ll need a regulator to control the flow rate. We’re talking a gentle, consistent stream, not a hurricane.

Filler Rod: The Metal Love Child

Unless you’re doing a technique called "autogenous welding" (which, honestly, sounds like a fancy car brand), you’ll be using filler rod. This is a thin rod of metal that you dip into your molten puddle to add material and fill the gap. It's the wingman to your welding torch. You’ll choose a filler rod that's the same or very similar to the metal you're welding. It’s like trying to glue two pieces of wood together with superglue and then using a bit of sawdust to fill the gaps – it needs to be compatible!

Safety Gear: The Unsung Heroes

Okay, this isn’t the fun part, but it’s the absolutely essential part. You wouldn’t go swimming in a shark-infested ocean without a cage, right? Welding is similar. You need protection.

- Welding Helmet: This is your shield against the blinding light and harmful UV rays. Get an auto-darkening helmet; it’s a game-changer. You can see what you’re doing without having to slam the shield down every second. It’s like having sunglasses that magically tint themselves when you need them.

- Welding Gloves: Thick leather gloves to protect your hands from heat and sparks. Think of them as your metal-handling superpowers.

- Welding Jacket or Flame-Resistant Clothing: Protect your arms and body from stray sparks and UV burns. No polyester shirts, please! They melt.

- Safety Glasses: Wear these under your helmet. Double protection is never a bad thing.

- Closed-Toe Shoes: Preferably leather boots.

The Dance Begins: Setting Up and Getting Ready

Alright, gear check complete. You’re looking less like a mad scientist and more like a cautious artist. Now, let’s get this metal party started.

Prepare Your Metal: Cleanliness is Next to Godliness (and Good Welds)

This is where many beginners stumble. You can have the best welder in the world, but if your metal is covered in oil, grease, rust, or paint, you’re setting yourself up for a bad time. It’s like trying to give someone a hug with a bunch of sticky candy wrappers stuck to your shirt – not ideal. You need to get it sparkling clean.

Use a wire brush (stainless steel is good for this), a grinder with a flap disc, or even some sandpaper to get down to bare, shiny metal. For really stubborn grease, a degreaser is your friend. Think of it as giving your metal a pre-party scrub.

Set Your Machine: The Amperage Tango

This is where you consult your welder’s manual. It’s usually the most boring bedtime reading you’ll ever do, but it’s important. For TIG welding, amperage is king. A general rule of thumb for DC welding on steel is roughly 1 amp per thousandth of an inch of thickness. So, if you’re welding 1/8th inch thick steel (that’s about 0.125 inches, or 125 thousandths), you’re looking at around 120-130 amps. This is just a starting point, and you’ll adjust based on how the metal is melting.

![TIG Welding Aluminum: The #1 GUIDE For Beginner [2021]](https://vietmfg.com/wp-content/uploads/2020/08/5-step-Process-768x384.jpg)

Don't be afraid to do a few practice beads on scrap pieces. It's like practicing your golf swing – you don't just step up to the big game without a few warm-up shots.

Set Your Gas Flow: The Gentle Breeze

Your gas regulator has a flow meter. For most TIG applications, you’ll want around 15-25 cubic feet per hour (CFH). Start in that range and listen to the gentle hiss of the gas. Too much, and you’ll be blowing your molten puddle around like a leaf in a hurricane. Too little, and your invisible bodyguard won't be doing a very good job.

Prepare Your Torch: Tungsten and Gas Lens

Your tungsten electrode needs to be sharp. You’ll grind it to a nice, sharp point. This helps focus the arc. Don’t use a grinding wheel that you use for other metals; dedicated tungsten grinders are best, or a clean, dedicated grinder. You’ll also make sure your gas lens is properly seated. This helps direct the argon flow more effectively.

The Art of the Arc: Striking and Welding

This is it. The moment of truth. Deep breaths. You’ve got your metal prepped, your machine humming, your gas flowing, and your helmet ready.

Striking the Arc: The Ignition Sequence

There are two main ways to start a TIG arc: high-frequency start and scratch start. High-frequency start is what most modern machines have. You just bring the tungsten close to the metal (about the thickness of a dime) and squeeze the trigger. The machine sends out a little spark to initiate the arc without you touching the metal. It's like a tiny, invisible lightning strike.

Scratch start is like lighting a gas stove – you gently "scratch" the tungsten against the metal. This is generally not preferred as it can contaminate your tungsten, but it works if your machine doesn't have HF start. For beginners, HF start is your friend.

Once the arc is struck, you want to maintain a consistent distance between the tungsten and the workpiece, usually around the diameter of your tungsten electrode. This is your arc length. Too far, and your arc gets unstable and wide. Too close, and you risk contaminating your tungsten.

The Molten Puddle: Your Focus Point

As soon as that arc strikes, you’ll see a tiny, intensely bright puddle of molten metal form. This is your playground. Your job is to keep this puddle moving and controlled. You’re not just holding the torch still; you're dancing with it.

The key to a good TIG weld is controlling that puddle. You're looking for a nice, consistent, even melt. Think of it like watching water boil – you want a steady simmer, not a violent, splashing boil.

Adding Filler Rod: The Delicate Touch

Now, for the filler rod. If you're welding a joint, you'll hold the filler rod in your non-torch hand. You’ll dip it into the leading edge of the molten puddle. The heat from the puddle will melt the filler rod, and you'll feed it in as needed. The trick is to dip and withdraw the rod rhythmically, keeping it just out of the arc itself so it doesn’t melt prematurely. It's a very subtle movement, like gently nudging something into place.

You're not just shoving the rod in. You're letting the heat of the puddle do the work. Imagine you're stirring a tiny pot of molten metal with a very thin, edible spaghetti strand. You dip, add a bit, pull back, dip, add a bit. You want to melt the filler rod into the puddle, not glob it on.

Torch Angle and Movement: The Artful Sway

Your torch angle is important. Generally, you want to keep the torch at a slight angle (about 10-15 degrees) pointing in the direction of travel. This helps push the molten puddle and protects it with the argon shield. You'll move the torch in a steady, consistent motion. Some people use a slight back-and-forth motion, while others use a consistent push. Find what works for you, but consistency is key.

Think of it like drawing a smooth line with a pen. You don't want jerky, stop-start movements. You want a fluid motion.

Troubleshooting: When Things Go a Little Wonky

Even the most seasoned welders have off days. If your weld isn't looking like a Pinterest-worthy masterpiece, don't fret. Here are a few common hiccups.

Porosity: The Pinhole Pests

If your weld looks like it’s got tiny little holes in it (porosity), it usually means you’ve got contamination. This could be from not cleaning your metal well enough, poor shielding gas coverage, or dirty filler rod. Double-check your prep work and ensure your gas flow is adequate.

Undercut: The Little Ditch

Undercut is a groove melted into the base metal alongside the weld. This usually happens when you’re running too hot or moving too fast. Slow down and control your amperage. Think of it like digging a tiny trench next to your intended path.

Lack of Fusion: The Unwelded Gap

This is when the filler metal and the base metal haven't properly fused. It’s like trying to stick two pieces of paper together with just a drop of water – they don't really bond. This is often caused by not getting the base metal hot enough or not directing the heat and filler rod properly. Make sure you’re getting a good, consistent melt.

Practice Makes… Well, Not Perfect, But Definitely Better!

Look, nobody becomes a TIG welding wizard overnight. It takes time, patience, and a willingness to burn through a few pieces of scrap metal. That’s what scrap metal is for – it’s your training ground.

Start with simple joints like butt joints (pieces placed edge-to-edge) and lap joints (pieces overlapping). As you get more comfortable, you can move on to corner joints and fillet welds. Don’t be afraid to experiment with different amperages and travel speeds. Listen to your machine, feel the heat, and watch that puddle.

TIG welding is a skill that’s incredibly rewarding. It allows you to create strong, beautiful welds that are often invisible or nearly so. It’s like being a surgeon for metal. So, grab your gear, be safe, and enjoy the process. That satisfying hum of the welder, the glow of the arc, and the feeling of creating something solid and lasting – it’s a pretty cool experience. Now go forth and make some shiny metal things!