How Do You Use A Grease Gun? Step-by-step Answer

Ever seen one of those cool-looking tools, sort of like a big, sturdy syringe, and wondered what in the world it does? That's likely a grease gun, and let me tell you, it’s a surprisingly satisfying tool to use. It’s not just for mechanics, though they love them! Anyone with a bit of machinery around the house or garage can find joy in wielding one.

Think of it as a precision delivery system for lubrication. Instead of messy tubs or cans, the grease gun neatly packs a punch of smooth, gooey goodness right where it's needed. It’s like giving your machines a little spa treatment, ensuring they run happily and smoothly.

The Magic of a Grease Gun

What makes a grease gun so much fun? It's the tangible aspect of it. You get to see, and even feel, the grease being forced into those tiny, important spaces. There’s a definite sense of accomplishment when you hear that satisfying squish or thunk as fresh grease fills a worn-out joint. It’s a little bit messy, a little bit powerful, and a whole lot rewarding.

It’s also about connection. When you’re using a grease gun, you’re actively participating in the well-being of your equipment. You’re not just a passive observer; you’re a hands-on caregiver. This connection can be surprisingly grounding in our increasingly digital world.

And let's not forget the visual! A shiny, well-maintained machine that runs like a dream is a beautiful thing. Using a grease gun is a small but vital step in achieving that pristine performance. It’s like being an artist, but your canvas is made of metal and your paint is thick, protective grease.

Getting Started: The Unboxing of Joy

So, you’ve got your shiny new grease gun. It might look a bit intimidating, but fear not! The process of getting it ready is part of the adventure. It’s a bit like preparing for a special recipe, where the ingredients themselves are exciting.

First, you need your grease cartridge. These come in all sorts of flavors, much like ice cream, but for machinery. You’ll want the right kind for your specific needs, but for general purposes, a good all-around chassis grease is a fantastic start. Think of it as the star ingredient.

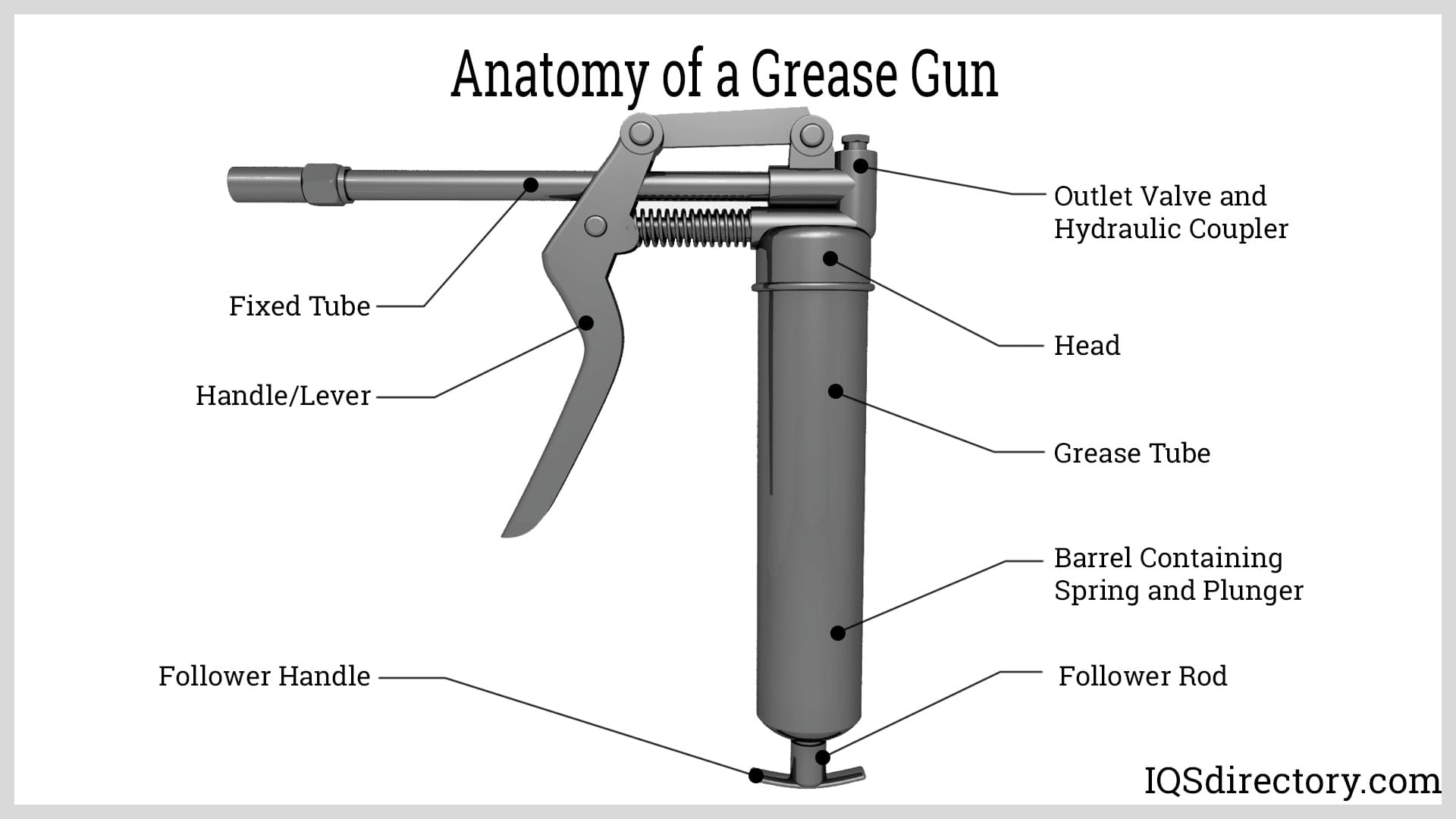

Now, let's prepare our trusty tool. You'll notice the barrel of your grease gun. This is where our delicious grease cartridge is going to live. It’s a cozy fit, designed to hold the grease securely and allow the gun to push it out with gusto.

Loading Up: The First Big Step

This is where the real action begins. You’ll typically unscrew the barrel of your grease gun. It might require a bit of a twist and pull, but it’s usually designed to be opened without too much fuss. Imagine opening a fancy thermos – it’s a similar kind of satisfying seal.

Once the barrel is open, you’ll see the empty space where the grease will go. Take your fresh grease cartridge. You might need to remove a plastic cap or a metal seal from the end. This is like unwrapping a present – a little bit of anticipation before the main event.

Now, slide the grease cartridge into the barrel. It should fit snugly. Make sure the end of the cartridge that the gun will push is facing the plunger end of the gun. This is crucial for the gun to work its magic. It's like loading a film into an old camera; you need to get it in the right way for the picture to develop.

After the cartridge is in, you’ll reattach the barrel. Screw it back on tightly. You want a good seal so that none of that precious grease escapes prematurely. This is where the power starts to build, like winding up a toy.

Priming the Pump: Getting the Grease Flowing

Before you can shoot grease with precision, you need to get the grease moving through the gun. This is called priming, and it’s a surprisingly simple yet vital step. It’s like priming a pump for water, ensuring the flow is consistent.

You'll usually find a plunger rod at the back of the grease gun. This rod needs to be pushed all the way in to connect with the back of the grease cartridge. Sometimes, you’ll pull it out to load and then push it back in. This is a key interaction between you and the tool.

Now comes the fun part of priming. You'll need to operate the trigger or the lever of the grease gun. You might need to do this a few times, and you might not see any grease come out at first. Don’t worry, this is normal! You’re essentially building up pressure inside the gun.

Keep pumping! You're looking for that moment when the grease starts to emerge from the tip. It might be a little blob, or a thin stream. Once you see that first bit of grease, you know you’ve successfully primed the gun. Victory is near, and it smells… well, it smells like grease!

The Main Event: Greasing Up Your Gear!

Now you’re ready for the most satisfying part: applying the grease! This is where your tool truly shines, delivering that protective, performance-boosting goodness.

First, locate the grease fittings on your equipment. These are usually small, metal nipples with a hole in the center. They look like they’re waiting for something, and they are! They’re designed to accept the tip of your grease gun.

Clean off any dirt or debris around the grease fitting. You don’t want to push old grime in with the fresh grease. A quick wipe with a rag will do the trick. We're aiming for clean and efficient delivery!

Press the tip of the grease gun firmly against the grease fitting. It should form a tight seal. This is important so that the grease goes where you want it, not spraying out everywhere like a mini-fountain of doom.

Now, squeeze the trigger or operate the lever. You’ll likely feel some resistance, and then, bam! You’ll see the grease being forced into the fitting. Keep going until you see a little bit of fresh grease ooze out around the fitting. This indicates that the old grease has been pushed out and the joint is now well-lubricated. It’s a very visual confirmation of a job well done!

Some fittings might take more grease than others. Listen to the sound and feel. You’re not trying to explode the joint; you’re gently filling it. Too much can be just as bad as too little, so aim for that sweet spot where you see fresh grease emerging. It’s a delicate dance of pressure and patience.

After the Party: Cleaning Up the Fun

Even after the greasing is done, there’s a little bit of cleanup to keep your tool happy and ready for its next mission. It’s like tidying up after a great meal.

Wipe off any excess grease from the grease fitting and the tip of your gun. A clean tool is a happy tool, and it makes the next job much easier. No one likes digging through a blob of dried grease to get started.

If you have a lever-style grease gun, you might want to pull the plunger rod back out slightly after you're done. This releases any internal pressure and makes it easier to open the gun next time. It’s a small step that makes a big difference.

Store your grease gun in a clean, dry place. Keeping it out of the dirt and grime will ensure it’s always ready to perform at its best. Think of it as tucking your valuable tool into a comfortable bed, ready for its next adventure.

Why It’s So Special

Using a grease gun is more than just a chore; it's an experience. It's about the tactile sensation of manipulating a robust tool, the satisfying hiss or squish as lubrication is delivered, and the visual reward of seeing machinery glide more smoothly. It’s a direct connection to the mechanics of the world around us.

It’s about empowerment. You’re taking care of your possessions, extending their life, and ensuring they perform their best. There's a quiet pride in knowing you've contributed to the smooth operation of your car, your lawnmower, or any other piece of equipment that relies on those little grease fittings.

So next time you see a grease gun, don't just see a tool. See an opportunity for a little hands-on fun, a chance to connect with your equipment, and a satisfying way to keep things running smoothly. Give it a try – you might just find yourself hooked on the simple, powerful joy of greasing!