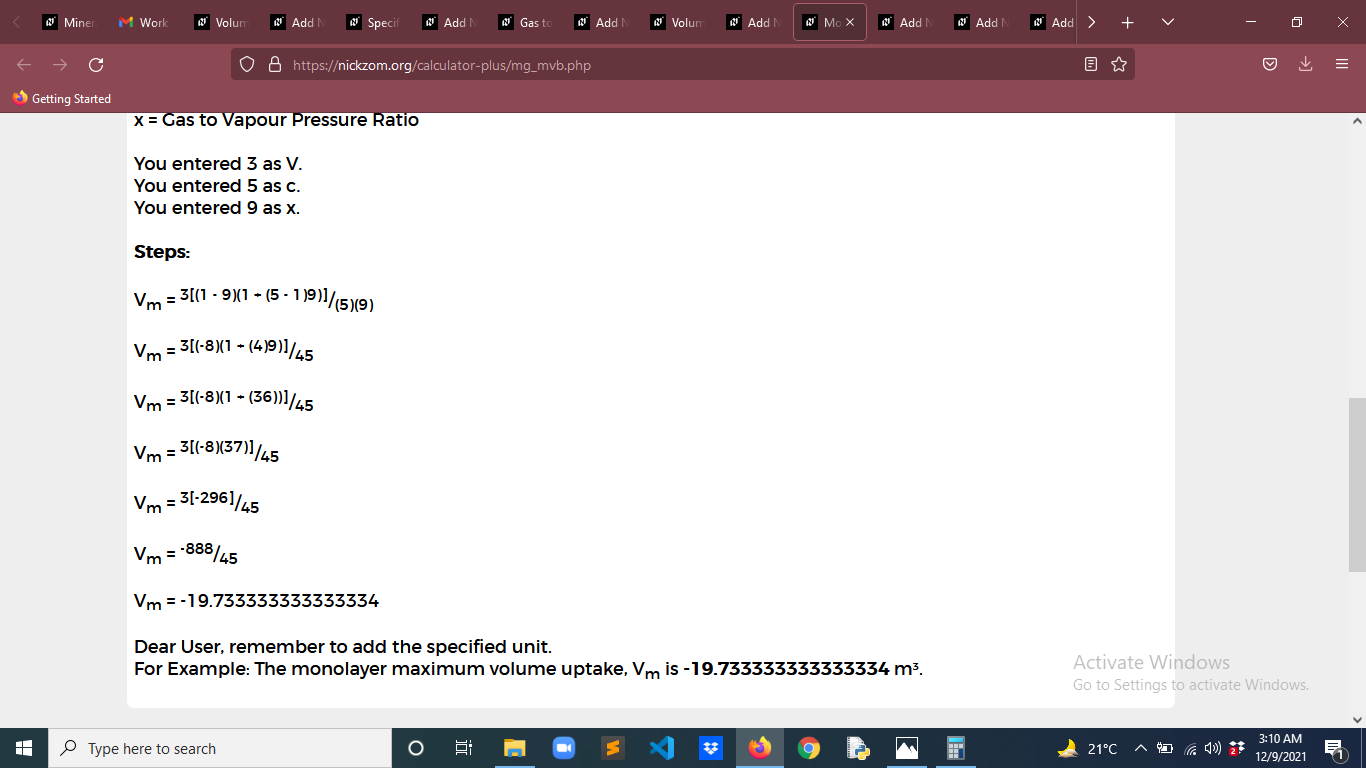

Determine The Volume Of The Monolayer From The Above Information.

Ever looked at a super-thin coating on something and wondered, "How much stuff is actually in there?" It might sound a bit niche, but understanding the volume of a single layer, a so-called monolayer, is surprisingly cool and super useful! Think of it like trying to figure out how much paint is really on a single, microscopic brushstroke, or how much of a special molecule is clinging to a tiny particle. It’s this kind of deep dive into the incredibly small that helps scientists and engineers develop amazing new technologies, from advanced electronics to life-saving medicines. It’s like being a detective, but instead of clues, you’re looking at atoms and molecules, and the ‘crime’ is often understanding how things behave at their most fundamental level.

The whole point of figuring out the volume of a monolayer is to get a precise measurement of a very, very small amount of material. Imagine you're trying to create a super-efficient solar cell, and you're coating it with an ultra-thin layer of a special material. You need to know exactly how much of that material you've used to make sure it works perfectly. If you use too little, it won't be effective. If you use too much, it might be a waste of resources or even hinder performance. So, determining the volume of this single layer, this monolayer, allows for incredibly accurate control and understanding of these delicate coatings.

The benefits are enormous! For starters, it's all about precision. When you're working at the nanoscale, even a tiny variation can make a huge difference. Knowing the exact volume of a monolayer helps researchers:

- Optimize Material Usage: No more guessing! This ensures that just the right amount of precious or expensive material is used, leading to cost savings and reduced waste.

- Enhance Performance: For applications like catalysts, sensors, or coatings, the exact thickness and volume of the monolayer directly impact how well they function.

- Reproducibility: Scientific experiments and manufacturing processes need to be repeatable. By precisely controlling the monolayer volume, researchers can be confident that their results will be the same every time.

- Develop New Materials: Understanding how to create and measure monolayers is fundamental to developing entirely new materials with novel properties.

So, how do we get this magical information? It’s not like you can just grab a tiny ruler! Scientists use a variety of clever techniques. One common method involves something called ellipsometry. Imagine shining a polarized light beam onto the surface and observing how the light changes when it reflects off the monolayer. The way the light's polarization is affected tells us a lot about the thickness of the layer. Another powerful tool is atomic force microscopy (AFM). Think of an AFM as an incredibly sensitive stylus that can "feel" the surface of a material, atom by atom. By scanning across the surface with and without the monolayer, we can measure the height difference, which, combined with the area, gives us the volume. Sometimes, techniques like quartz crystal microbalance (QCM) are used, where a tiny crystal oscillates, and the addition of a monolayer changes its frequency. The amount of mass added can then be calculated, and with knowledge of the material's density, the volume can be determined.

Let's consider a simplified scenario to illustrate the principle. Suppose you're laying down a layer of a specific molecule on a flat surface. You know the area of the surface you've covered, let's call it Area. You also have a way to figure out the thickness of that single layer, which we'll call Thickness. For a simple, flat layer, the volume is, you guessed it, just Volume = Area × Thickness. The "fun" and "engaging" part comes in how accurately we can measure both the Area and the Thickness at such incredibly small scales. For instance, if we're depositing a specific material onto a silicon wafer, and we know the wafer's exact surface area and use ellipsometry to determine the monolayer thickness is, say, 0.2 nanometers (that's 0.2 billionths of a meter!), we can then calculate the total volume of that monolayer across the entire wafer.

What if the surface isn't perfectly flat? Well, that's where things get even more interesting! Many materials we work with have complex surfaces, like nanoparticles or porous membranes. In these cases, simply multiplying the geometric area by the thickness won't cut it. We need to account for the actual surface area available for the monolayer to deposit on. Techniques like gas adsorption (think nitrogen molecules sticking to a surface) can help determine the total effective surface area, even in tiny pores. Once we have this effective surface area and the measured thickness (again, from methods like ellipsometry or AFM), we can get a much more accurate volume for our monolayer, even on incredibly intricate structures.

The concept of a monolayer is foundational in fields like surface science, materials chemistry, and nanotechnology. It's the building block for creating advanced functional surfaces. For example, in the development of new catalysts, the number and arrangement of active atoms on the surface, often in a monolayer, dictate the reaction efficiency. Similarly, in biological applications, attaching a specific protein or drug molecule as a monolayer to a nanoparticle can direct it to target diseased cells. The ability to accurately determine the volume of these monolayers is crucial for designing and controlling these sophisticated systems. It allows us to move beyond just creating things at the nanoscale to truly understanding and manipulating them with incredible precision. It's this control and understanding that unlocks future innovations, from bendable electronics to personalized medicine, making the seemingly mundane task of measuring a single layer a cornerstone of scientific progress.